The azimuth motor is well protected by its housing, so in the two years of nearly continuous operation it has not given any hint of a problem. During an inspection this autumn I met only a group of shivering, dying wasps, which had somehow found their way in and huddled together for a bit of warmth ...

As I have been experimenting with band-pass filters, the focal assembly has received frequent visits. But as it does not contain any components subject to mechanical wear, and the lonely small spiders do not do any harm, this part does not need any attention.

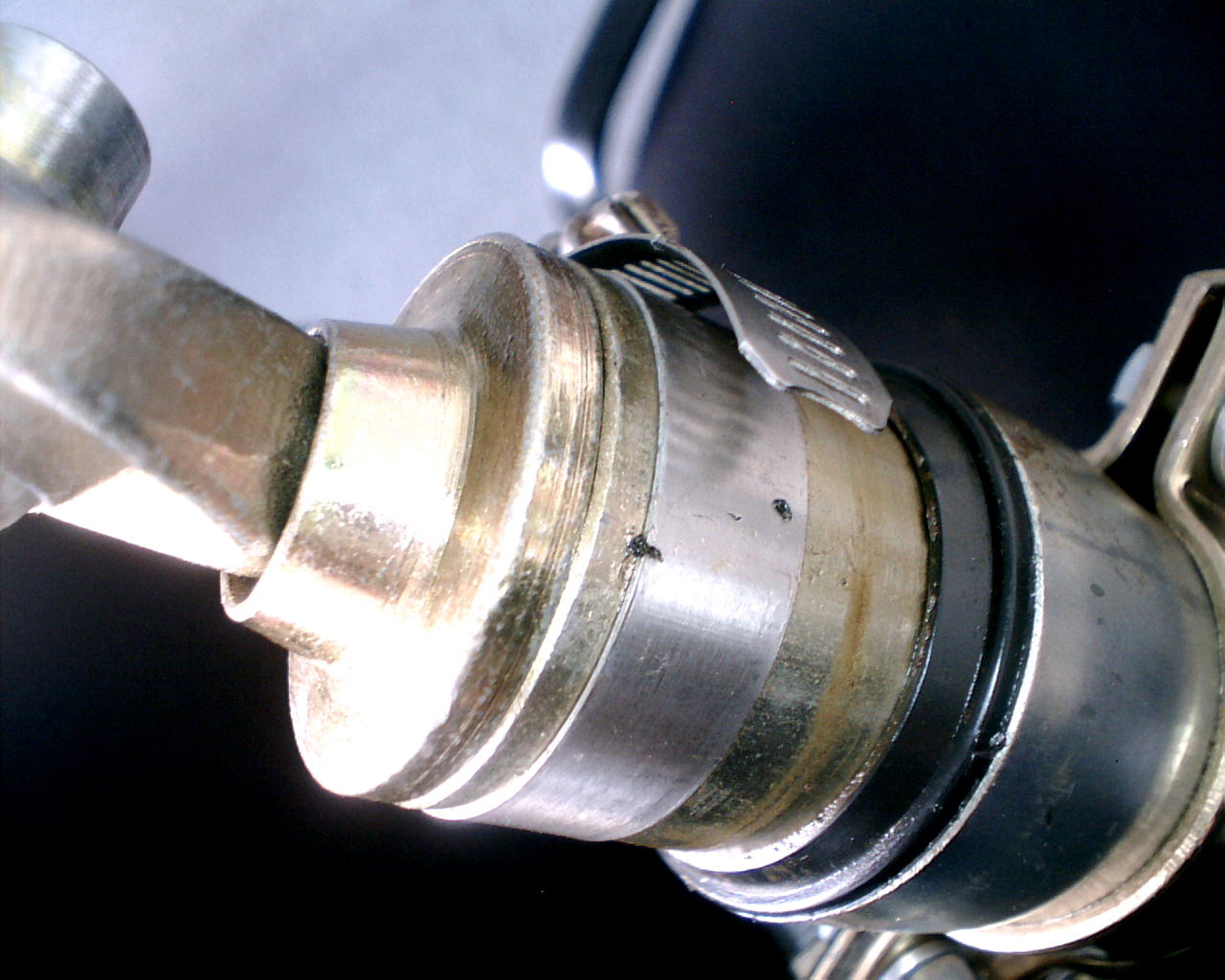

However, the linear actuator ("pushrod") that does the elevation control did develop problems: Although it should be maintenance-free, it is exposed to the weather, and evidently rain water had penetrated its interior. Initially, it was noticed from the observational data that sometimes the elevation was not correct, and finally the telescope could not be moved in elevation. The inner tube revealed signs of corrosion

The reason for this problem might be rain water seeping in through some gaps where the eye holding the mounting bolt is fixed to the inner tube of the pushrod:

Here is a report about repair work done in 2013 of the pushrod and the motor housing:

Report on Repair in 2013 (1.2 MB)

| Top of the Page | Back to the MainPage | to my HomePage |

last update: Jul. 2013 J.Köppen